Table of Contents:

Table of Contents:

As plant-based food makes its shift from vegans and vegetarians to the mainstream of American diets, manufacturers are expanding to produce these types of food. Plant-based diets are comprised of minimally processed fruits, vegetables, grains, nuts, and seeds. Plant-based foods have both nutritional benefits and a positive environmental impact. The Global Plant-Based Meat Market was valued at USD 9.57 billion in 2024, and is projected to reach USD 21.81 billion by 2030, rising at a CAGR of 14.72%.[1]

Same Food Manufacturer, New Opportunity

Big meat companies are diving into plant-based food products by utilizing new and unused spaces. This booming market gives companies a new product venture that fits within the same parameters of their already existing manufacturing plant. The food and beverage industry requires strict regulations from floor to ceiling that companies with HACCP International certified products can provide. HACCP is a process control system that identifies hazards and certifies products as food safe.

How Seamless Urethane Flooring Supports a Food Processing Facility

Resinous floors for the food processing industry withstand organic acids, hot water washdowns and harsh cleaning chemicals on a routine basis. Urethane floors cure to a hard, impact-resistant surface that can stand up to high and cold temperature as well as temperature changes. This seamless flooring is durable and easy to maintain under demanding industrial conditions. The highest quality flooring will exceed FDA and USDA guidelines and meet HACCP standards. Resinous floors are acceptable for all areas of food processing facilities including food and drug preparation and storage rooms, waste disposal and washing areas, as well as refrigerator and freezer areas.

Resinous flooring is poured into spaces to become a part of the building’s structure. The benefit for plant-based food manufacturers is that resinous floors have no cracks or ridges, so by nature they are anti-microbial because microorganisms have no place to harbor and grow. In addition, resinous floors can be pitched to drains, so that puddles and pooling water, where microorganisms multiply, can be eliminated. This allows food processing businesses to adhere to strict regulations and health codes. Resinous flooring can also withstand the impact of equipment like forklifts and moving carts throughout the plant. These seamless floors also come in a range of colors and designs, including the ability to display a custom brand logo.

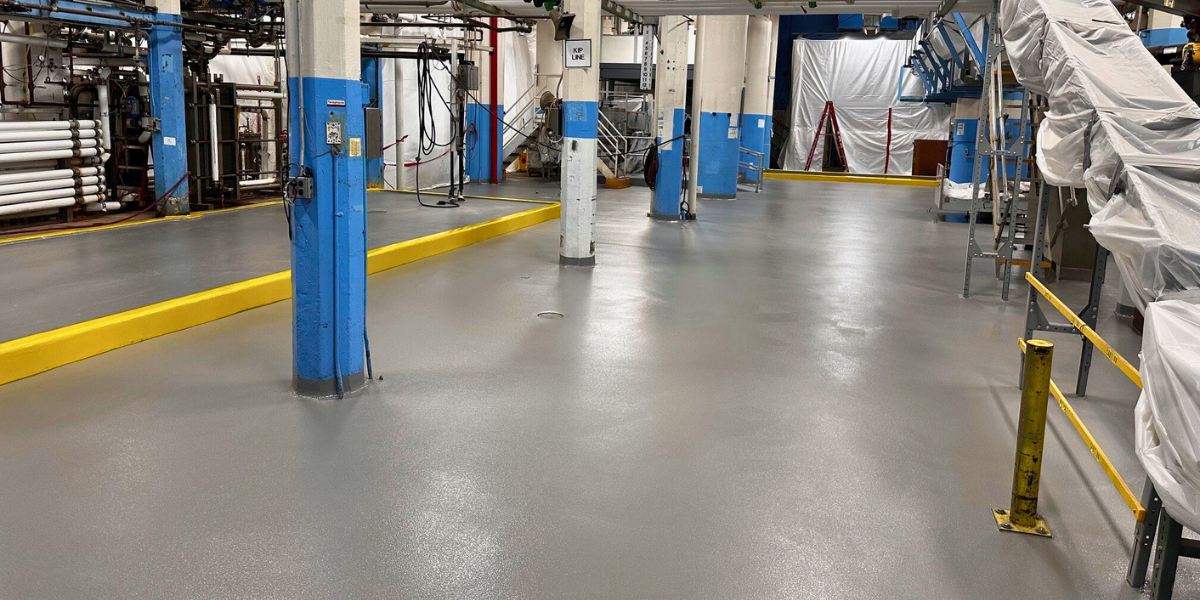

This food production space features slip-resistant, easy-to-clean flooring -- prioritizing safety and sanitation in every step of the operation.

This plant-based food manufacturing facility features high-performance seamless floors designed for impact resistance and hygiene support.

What About Sustainability?

With the plant-based market seeing a spike in growth, many organizations are working to improve sustainability measures across the board. Sustainable or “eco-friendly” floors contribute to a company’s commitment toward reducing its carbon footprint, meeting environmental regulations, and encouraging the use of recycled materials. Some seamless floors utilize rapidly-renewable and/or recycled materials in their production. In addition, such poured-in-place floors reduce the carbon footprint because they do not end up in landfills like traditional flooring products. When trying to expand into an eco-friendly market, sustainable efforts go a long way!

Durable, hygienic flooring supports contamination control in this high-traffic food processing zone -- built to withstand constant cleaning and heavy equipment.

Built for performance, the flooring in this packaging zone maintains a seamless, sanitary surface.

Stonhard Urethane Flooring Systems

Stonclad urethane mortar flooring systems provide all the benefits mentioned in this article, including rapidly-renewable castor oil-based formulas, and more.

Want to learn more about hygienic design in food manufacturing plants? Download our complimentary whitepaper: A Total Hygienic Solution Floor Drain And Curb Research

About Stonhard

Stonhard is the unprecedented world leader in manufacturing and installing high-performance polymer floor, wall and lining systems. Stonhard maintains 300 territory managers and 200 application teams worldwide who will work with you on design specification, project management, final walk-through and service after the sale. Stonhard’s single-source warranty covers both products and installation. Contact us to learn more about our HACCP-certified flooring systems and other specialized solutions for the Food & Beverage industry.

Related Articles

Loving this Content?

Subscribe to upcoming topics!