Table of Contents:

Table of Contents:

Newly-poured concrete contains significant amounts of excess moisture that must be allowed to evaporate during a curing process of at least 28 days in order to avoid bubbling or peeling epoxy and other problems.

New concrete can often appear dry well before it is ready for an epoxy coating. Many people wonder how soon an epoxy coat can be applied after laying down the concrete.

While it may be tempting to finish the job quickly, the best course of action in every case is to wait for the concrete to dry properly. How long to wait and why it is necessary will be covered in this blog.

Before applying an epoxy coating, make sure the concrete slab has adequately dried.

For new concrete to achieve its ultimate strength, excess water in the concrete mix must be allowed to evaporate. Proper preparation of concrete and the concrete surface is essential before any epoxy coating can be applied.

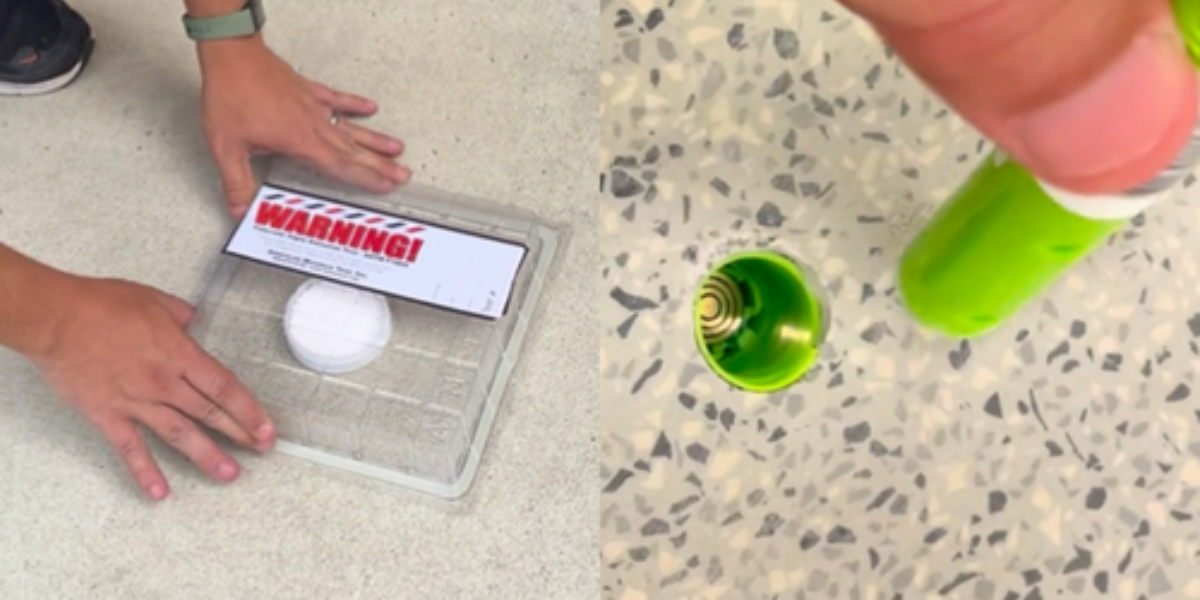

Different areas of the slab may vary in moisture levels depending on how the concrete was mixed. Testing for moisture and moisture vapor, which we have covered in our StonTalks video series, is the most important way to determine whether a slab is ready for coating.

Curing New Concrete

Newly installed concrete has a high moisture content. This characteristic prevents an epoxy floor coating or other resinous system installation from being applied too soon. If the flooring system is installed before proper moisture testing, bubbling, peeling, and a host of other problems are bound to occur.

Due to these risks, it is recommended to allow new concrete a curing period of at least 28 days. The system installed will determine the acceptable moisture level. There are even cases – such as in the event of local air temperature and humidity levels – where it can take as long as 60 days before the new concrete has cured enough for coating.

RH testing of concrete is a tried-and-true method of determining moisture levels in concrete.

Testing Moisture Levels

Before a finished floor can be installed, professionals use a variety of testing methods to ascertain Moisture Vapor Transmission (MVT) levels in the concrete slab.

While many surface-based methods have been used over the years, decades of research in Europe and the United States clearly show that Relative Humidity (RH) testing is the most reliable method for accurately determining the moisture condition of concrete floor slabs.[1]

This method entails drilling holes into the slab, followed by the insertion of a humidity probe. The resulting measurement makes this test a very accurate way to measure MVT.

A shot blaster can be used to strip sealers from the concrete surface.

Checking For Sealer and Cracks

An installer will test to see if a sealer was previously used on the concrete. They will do this by testing whether water beads up on the surface. If this is the case, then removing the sealer by shot blasting before applying epoxy is recommended.

Previous coatings and/or paints may also be removed during this stage. Cracks and other concrete defects should be filled and stabilized before applying epoxy coating.

What If There Are High Moisture Levels?

In the event of high moisture content in the concrete, some light-duty and permeable sealers can be applied to the slab. However, these will be single-component liquids with minimal resin content that are mopped or rolled onto the slab, resulting in a thin film that merely dries on the slab surface.

These sealers do little more than provide a surface sheen for a short period of time. In commercial and industrial facilities, heavy traffic can wear this sealer away quickly.

Why use Epoxy or Resinous Coatings?

In contrast to sealers, epoxy and other resinous floor coatings with blended components “cure” rather than simply dry. These high-performance systems offer outstanding durability to a slab surface, along with chemical resistance and other benefits that save facilities time and money over the long-term.

Epoxy coatings can be found in industrial and commercial settings including healthcare institutions, food and beverage facilities, pharmaceutical laboratories, offices, and more. Decorative epoxy coatings are available in a variety of colors and styles, including quartz, solid color, metallic, and flake.

Epoxies are durable and highly resistant to many chemicals and abrasive liquids, as well as extreme wear and impacts. These attributes make them ideal for settings with high foot or vehicle traffic. Some epoxy coatings also provide protection against temperature extremes, such as those found in commercial kitchens.

Epoxy coatings can also be configured with many surface textures that provide differing levels of slip resistance – a desirable benefit for businesses looking to ensure employee and customer safety.

Epoxy floors provide superior impact, abrasion, and chemical resistance.

Rely on the Experts for Installation

Preparing a concrete floor is a labor-intensive process, as is applying the epoxy coating. To avoid errors, it is best to rely on a professional flooring contractor.

Contact Stonhard and your local territory manager or architectural engineering & design representative will be happy to help answer any questions you have about the installation of your epoxy or resinous coating.

Stonhard is recognized globally for solving flooring problems. We are the world’s largest turnkey, seamless flooring contractor committed to comprehensive management of each project from construction documentation to the final details. No hidden costs, no sudden change orders, and scrupulous attention to details.

About Stonhard

Stonhard is the unprecedented world leader in manufacturing and installing high-performance polymer floor, wall and lining systems. Stonhard maintains 300 territory managers and 200 application teams worldwide who will work with you on design specification, project management, final walk-through and service after the sale. Stonhard’s single-source warranty covers both products and installation. Contact us to learn more about our precision installation methods and specialized products.

Related Articles

Loving this Content?

Subscribe to upcoming topics!